SAVEDRY ® system

Moisture measurement / Drying control / Leakage detection

SAVEDRY® is a measuring system which continuously evaluates moisture content of refractory. Leaks in the cooling system of the furnace can be reliably detected and located if water encroaches into the refractory material. In addition, the drying process of linings can be permanently controlled to optimize furnace up-time. Danger due to overheating (by burner) or residual moisture (premature termination) can be avoided.

|

|

| Hardware components of the SAVEDRY ® system Left: Control and visualization unit (C&V) Right: Measuring unit |

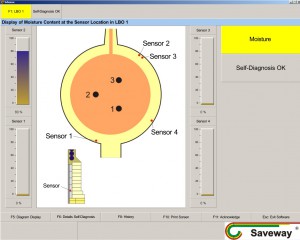

Operator display of the SAVEDRY ® system using the example of an arc furnace |

Application

Application

The extraordinary flexibility of the technology enables the adaption to many customized tasks.

Application examples:

+ Arc furnace

+ Ladle

+ Graphitization furnace

Benefits

Benefits

Significantly improves safety

for operating staff and plant, because furnace damage and molten breakouts can be safely avoided

Optimize operating costs

by reducing the costs of maintenance and production losses

Increase equipment up-time

based on the risk-free increase of service life and predictability of relining

Targeted melting process improvment

by optimizing the sinter heat

Pruduct attributes

Product attributes

- Simple and safe handling

- Robust equipment for working in harsh environments

- Multifunctional application on various furnaces

- Easy integration into existing networks

- Automatic self-diagnosis of the all SAVEDRY® devices

- Electrically autonomous measuring system

- Fast remote service via TeamViewer

- Continuous data storage

- Easy integration into furnace controls

- Combinable with SAVEWAY® and SAVELINE®

SAVEDRY ® sensor:

- Different versions

- Length: variable

- Flexible (independet of the sensor type)

Functionality

Functionality

The electrical resistance is dependent on the moisture content at the sensor location. The display of the current moisture content appears as a percentage on a separate bar graph for each segment. Excessive lining is indicated by additional optical signals. There are several types of sensors available that are specifically selected for the measurement task and the monitored aggregate.

Features

Features

Additional external dual display

This separate parallel display always shows the same screen as on the control and visualization unit, without time delay. Longer distances can be reached, with a maximum distance of 100 m (328 ft) to the control and visualization unit.

There are two different variants:

|

|

| External opti panel | External TFT display |

Furnace shell identification

With the help of this feature, the system automatically identifies which furnace shells are currently connected to the system. The identified furnace shell will be monitored in the wear and history Display.