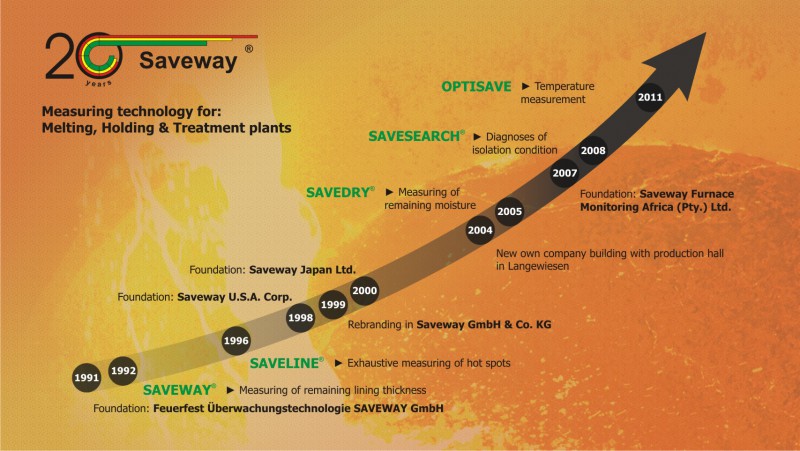

Company History

When Dr. Manfred Hopf established the company “Feuerfeste Überwachungstechnologie Saveway GmbH” together with the Herrmann family, nobody thought about today´s global economic dimensions. His goal was to develop innovative technologies in safety monitoring. The business concept developed during his degree dissertation at the Technical University of Ilmenau, which already dealt with safety monitoring.

Team at the foundation of the company – professionals in the electronic, foundry and refractory industries

With passion, they worked on a product with which you can continuously monitor the remaining lining thickness during furnace operation. In 1992 it was done – the first SAVEWAY ® system was installed on a 2 ton capacity medium frequency furnace and there began a new era in furnace safety. Until then, it was only the “right gut feeling” of the operator, that the furnace was shut down in time. Now they could visualize concealed wear with modern technology – a requirement for maximum safety for both man and machine.

A technology-based German company had succeeded in bringing a highly developed safety monitoring system to the market. In 1999, the company became “Saveway GmbH & Co. KG” with Dr. Manfred Hopf as sole managing owner and president.

It was necessary to develop a second product and measuring technique to monitor certain areas of channel furnaces. A serious runout on a holding furnace was crucial to install the first SAVELINE ® system in 1996. Around the same time, the first SAVEWAY ® technology was launched in the steel, ceramic and glass industries. In primary metallurgy/smelting it was first used in 1999.

In 2004, the increased space required due to the growing number of customers and employees necessitated a move to a larger building. Remaining in the original location of Langewiesen, the new building was inaugurated on 2nd July 2004. It includes large production areas optimized for the specific needs of the company.

The new company building at the headquarters in Langewiesen / Germany

Serving various industries, we are always met with new requirements to be innovative. So Saveway developed the SAVEDRY ® system in 2005, to monitor residual moisture and drying of refractories. In 2008, stimulated by a request for a selective shunt monitoring from the foundry industry, the SAVESEARCH ® system was patented, which is used for preventive maintenance of induction furnaces.

Two fibre-optic temperature measurement systems for process optimization and wear monitoring are the latest products. Manly used to control smelting equipment in the primary metallurgy, the two technologies are summarized under the product name OPTISAVE. In this context embedded linear sensors in water-cooled copper coolers has been patented by Saveway. Worldwide a total of five patents have been issued for this innovation.

Subsidiary companies in North America, Japan and South Africa were established in order to provide customers with sales and service support. The sole manufacturing base remains in Langewiesen. Close cooperation with customers, universities and professional associations is important for the development of innovative ideas and practicle achievements. The annual expert conference organized by Saveway provide a platform for exchanging experiences and constructive discussions with colleagues from the industry.

What began as a degree dissertation at the Technical University in Ilmenau, has become a industry-wide standard for safety. Saveway has forged a reputation of providing each customer with knowledge about how their particular practices influence lining life; resulting more efficient operations and optimal safety. With innovative products, a professional and dedicated team and three subsidiaries worldwide, we are well prepared to continue writing the success story – true to the motto:

Success through innovation!

Company history at a glance